Coapt needed a solution for producing custom housings for electronic prosthetics control systems that were durable, lightweight, and could be quickly adapted to different patient needs. Traditional manufacturing methods could not meet the precise requirements and speed needed for custom prosthetic parts.

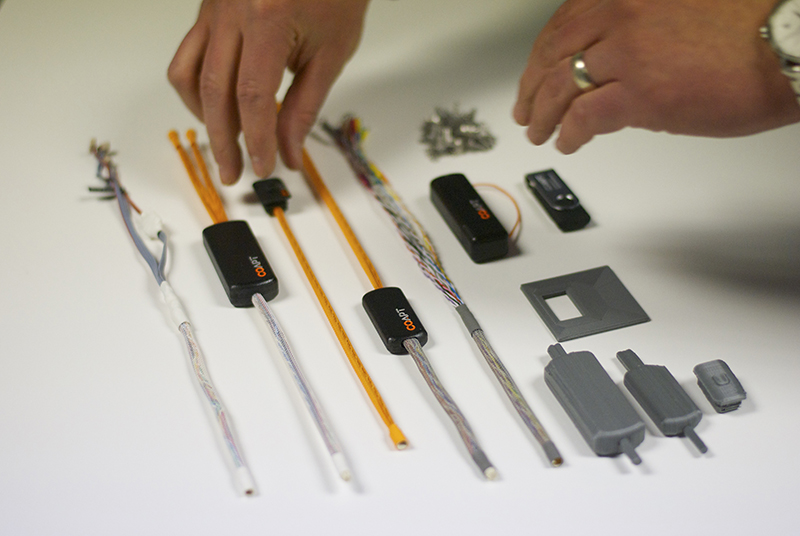

Customized housings for control systems in highly customized prosthetics

Summary

Challenge

Solution

Coapt adopted HP’s 3D printing technology with HP 3D HR PA 12 material to produce high-quality, custom housings for the electronic prosthetics control system. This allowed them to create parts with complex geometries and rapid turnaround times, improving the overall product performance and fit for users.

Value

3D printing enabled faster production and more accurate, customizable prosthetic components. The use of HP 3D HR PA 12 material resulted in strong, durable housings, enhancing both the functionality and comfort of the prosthetic devices while reducing time-to-market.

Products & Services

- HP MJF Technology

- HP 3D HR PA 12 Material

- Post-processing: Bead blasting

- In-house design and integration

AM I Navigator Maturity Model

0

1

2

3

4

5

S0

S1

S2

S3

S4

AM is fully integrated into the business strategy for producing customized orthotics and prosthetics, driving efficiency and sustainability.

S5

PD0

PD1

PD2

PD3

PD4

PD5

AM is used for designing custom repair kits for marine propulsion systems, providing tailored solutions to meet specific needs in boat maintenance.

Could further specify the role of DfAM in optimizing the design process.

M0

M1

M2

M3

M4

The use of HP 3D HR PA 12 material provides the necessary strength, durability, and suitability for medical applications.

M5

PE0

PE1

PE2

PE3

PE4

DfAM principles and material testing have been effectively implemented to optimize the production of customized orthotics and prosthetics.

PE5

PS0

PS1

PS2

PS3

PS4

AM supports flexible, small-batch production, ideal for customized medical devices, reducing lead times and improving responsiveness.

PS5

ME0

ME1

ME2

Manual process.

ME3

ME4

ME5

Q0

Q1

Q2

Q3

Q4

Quality control is maintained through stringent design and material selection, ensuring that the products meet medical device standards.

Q5

MS0

MS1

MS2

MS3

Regular printer maintenance.

MS4

MS5

ES0

ES1

ES2

ES3

ES4

AM allows for more efficient use of materials, reducing waste compared to traditional methods.

ES5

PO0

PO1

PO2

PO3

Developing additional AM offering to existing machine business.

PO4

PO5

Evaluate your additive manufacturing capabilities across 10 different dimensions.

Start Self-Assessment